Automatic Packing Machine

Packaging is a critical stage in the fertilizer production process. It not only ensures that the product reaches the customer in the best possible condition but also plays a vital role in maintaining the integrity and effectiveness of the fertilizer. Manual packaging can lead to inconsistencies in weight, spillage, and contamination, which can impact the quality of the product and lead to financial losses. An Automatic Packing Machine addresses these issues by automating the packaging process, ensuring that each bag or container is filled with the precise amount of fertilizer, sealed securely, and labeled accurately.

Key Features

LANE Automatic Packing Machine is designed with the specific needs of the fertilizer industry in mind. Here are some of the key features that make it an ideal choice for fertilizer manufacturers:

- High-Speed Operation: The Automatic Packing Machine is capable of handling high-volume production lines, packaging large quantities of fertilizer quickly and efficiently. This high-speed operation helps manufacturers meet demand while minimizing downtime.

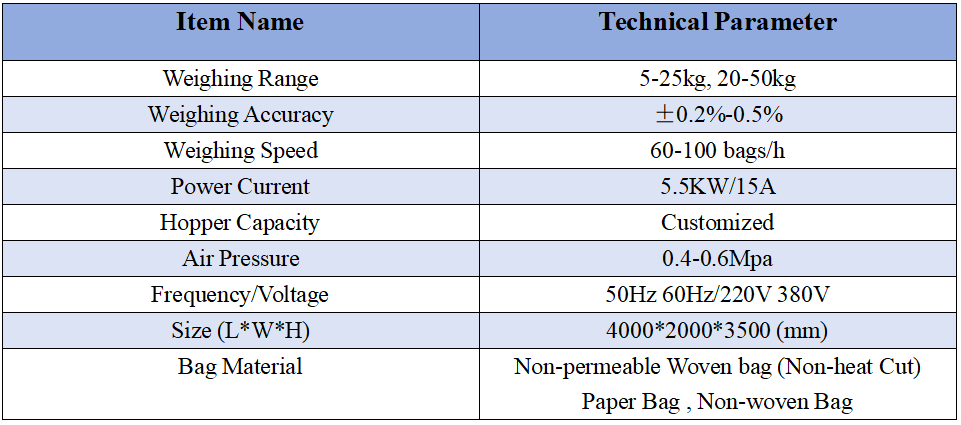

- Precision Weighing and Filling: Accurate weighing is crucial in fertilizer packaging to ensure that each package contains the exact amount of product. LANE Group’s machine is equipped with advanced weighing systems that provide precise measurements, reducing the risk of underfilling or overfilling.

- Versatility in Packaging Types: Whether it’s granular, powdered, or pelletized fertilizer, LANE Group’s Automatic Packing Machine can handle various forms of fertilizers. The machine is compatible with different types of packaging materials, including bags, sacks, and containers of various sizes.

- Robust Construction: Fertilizer can be abrasive and corrosive, so the packing machine is constructed with durable materials that withstand the harsh conditions of the fertilizer industry. The machine’s components are designed to resist wear and tear, ensuring long-term reliability.

- Advanced Sealing Mechanism: Proper sealing is essential to protect the fertilizer from moisture and contamination. The machine features an advanced sealing mechanism that ensures each package is securely sealed, preserving the product’s quality during storage and transport.

- Automated Labeling and Coding: In addition to packaging, the machine can be integrated with labeling and coding systems that automatically apply labels and print important information, such as batch numbers, production dates, and product details, on each package.

- User-Friendly Interface: The Automatic Packing Machine is equipped with an intuitive control panel that allows operators to easily monitor and adjust the packaging process. This user-friendly interface reduces the learning curve and enables quick setup and changeovers.

- Energy Efficiency: Designed with sustainability in mind, LANE Group’s machine is energy-efficient, helping manufacturers reduce operational costs and minimize their environmental footprint.

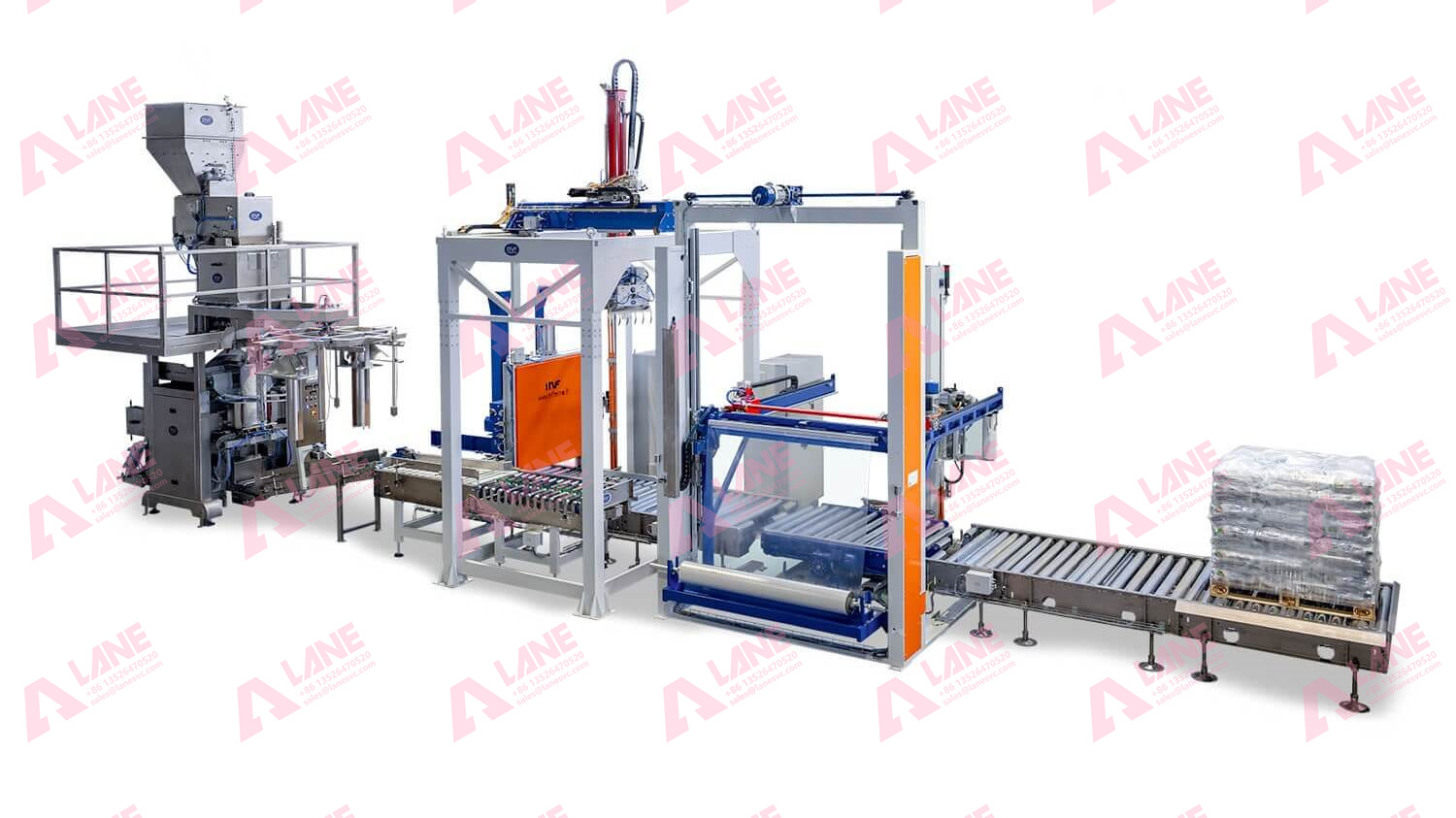

Pictures of Product

Application

LANE Automatic Packing Machine is versatile and can be used in various fertilizer packaging applications, including:

- Granular Fertilizers: The machine efficiently handles granular fertilizers, ensuring that each package is uniformly filled and securely sealed to prevent spillage.

- Powdered Fertilizers: For fine or powdered fertilizers, the machine provides accurate weighing and careful handling to minimize dust generation and product loss.

- Pelletized Fertilizers: Pelletized fertilizers require precise filling to maintain product consistency, and LANE Group’s machine is equipped to handle this task with precision.

- Custom Packaging Solutions: Whether the requirement is for small retail packs or large industrial sacks, the Automatic Packing Machine can be customized to meet specific packaging needs, ensuring that every package meets quality and safety standards.

Benefits

Implementing LANE Automatic Packing Machine in fertilizer production offers several significant benefits:

- Increased Productivity: By automating the packaging process, the machine increases throughput, allowing manufacturers to package more fertilizer in less time.

- Consistent Quality: The machine’s precision ensures that each package is consistent in weight and quality, enhancing customer satisfaction and reducing the likelihood of product returns.

- Reduced Labor Costs: Automation reduces the need for manual labor, lowering labor costs and reducing the risk of human error in the packaging process.

- Enhanced Safety: The machine is designed with safety features that protect operators from potential hazards, contributing to a safer work environment.

- Sustainability: The machine’s energy-efficient design and ability to reduce waste make it an environmentally friendly choice for fertilizer manufacturers.

If you want get more imformation, Contact us!

About LANE

Latest Articles & Tips

More-

01/03

Key Components in a High-Quality DSP Fertilizer Formula

read more -

12/26

MAP Granular Fertilizer Production Line

read more -

09/07

read more5 Upgrades to LANE MAP Fertilizer Production Line to Boost Yields by 25%!

-

09/26

read moreTransforming Rock into Riches: Inside the World of Phosphate Fertilizer Production Line